About us

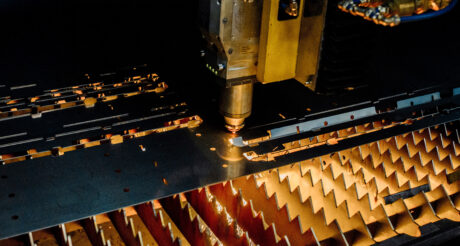

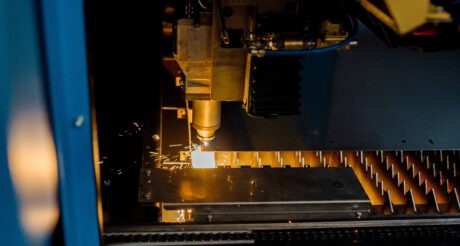

Navicut produces complexes for high-speed metal cutting with a fiber laser and linear motors. The Navicut machines are leaders in such parameters as productivity, price/quality ratio, processing cost of parts to be cut. We supply machines to the European Union and the USA, where we successfully compete with the best models.

In 2001 Navicut company began its activities in the production of metal laser cutting machines. During the first two years, a team of graduates from top technical universities conducted research and development.

For 22 years, we have achieved good results, several factories for the production of laser cutting machines have been opened. A wide range of equipment has been created, which allows solving any problems in the field of laser cutting of metal. Bringing our machine models to technical perfection, we have achieved very high quality finished products, outstanding processing speeds with high laser power.

All these parameters make our machines competitive in the European and world markets, and technical innovations allow us to offer favorable prices for our customers.

Patented “wing” system one synchronous linear electric drive is used for movement on each axis, unlike functional analogues with two or more motors per axis. This eliminates the need for synchronization and, as a result, significantly increases reliability of the equipment

Ease of use Models with a working area up to 4950x2050 do not require a special foundation

Design advantages High rigidity and vibration resistance of the machine ensure good quality and accuracy of processing in the entire range of dynamic parameters

Composite materials Composite Y-beam is much lighter and, at the same time, stronger than metal beam of the functional analogues, which allows to reduce vibrations and increase the dynamics of processing

Smart cabinet system Cabinet system with sensors for monitoring the position of doors and observation windows made of special glass ensures safe operation of the unit and protects the operator from laser radiation

Replaceable shuttle-type pallets Availability of replaceable shuttle-type pallets without lifting the lower pallet (cutting is carried out on two levels) allows for quick replacement of workpieces, with the pallet rewinding time not exceeding 15 seconds

Patented Developments Patented collimator allows the use of a standard QBH connector at high accelerations. Vacuum-tight design with a double-loop seal prevents air exchange with the surrounding space and dust ingress into the collimator

The best components Since 2015, Navicut has been equipping its systems with Precitec laser heads (for systems with powerful fiber lasers - 3 kW and more)

Customization The ability to design according to customer requirements allows us to be more customer-oriented

High speed laser cutting

to solve your problems

We are ready to surprise you with our possibilities

Our journey

Advanced technologies for laser cutting of sheet metal, pipes, profiles. Patented solutions quickly and efficiently help you solve your problems, regardless of the level of complexity of the work.

Alexey Korukov

Founder and technical leader of the group of companies. Responsible for strategic development and technology unit

Nikolaj Korukov

Responsible for the strategic development of the production area

Aleksandr Bikov

General Manager of Production in the Republic of Serbia

Alexey Bogdanov

Responsible for sales in the European market

Tijana Mihajlović

Production manager assistant in Republic of Serbia

Our contacts

Learn more about our product, chat with our managers or email us.

We will reply to you as soon as possible

Entity: Navigator machines doo Beograd-Vračar

Address: Kneza stracimira 34

Place: 11118 Beograd

Registration number: 21822094

Tax: 113198154

Navicut

Manufacture: Pita Maravića br.9g, Zrenjaninski put, Beograd 11210

Office: Pita Maravića br.9g, Zrenjaninski put, Beograd 11210

Privat policy

Copyright Navicut, 2001-2024. All Rights Reserved.

Next page Catalog machine