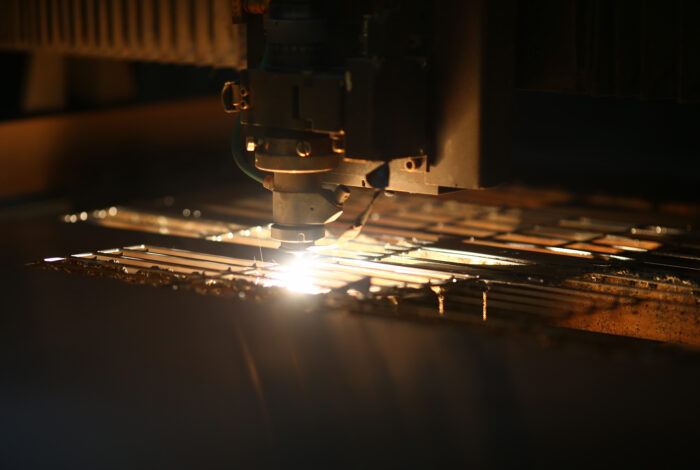

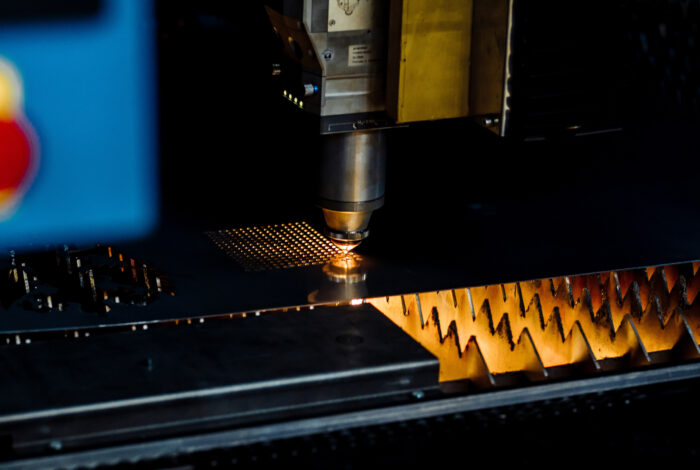

“Wing” system

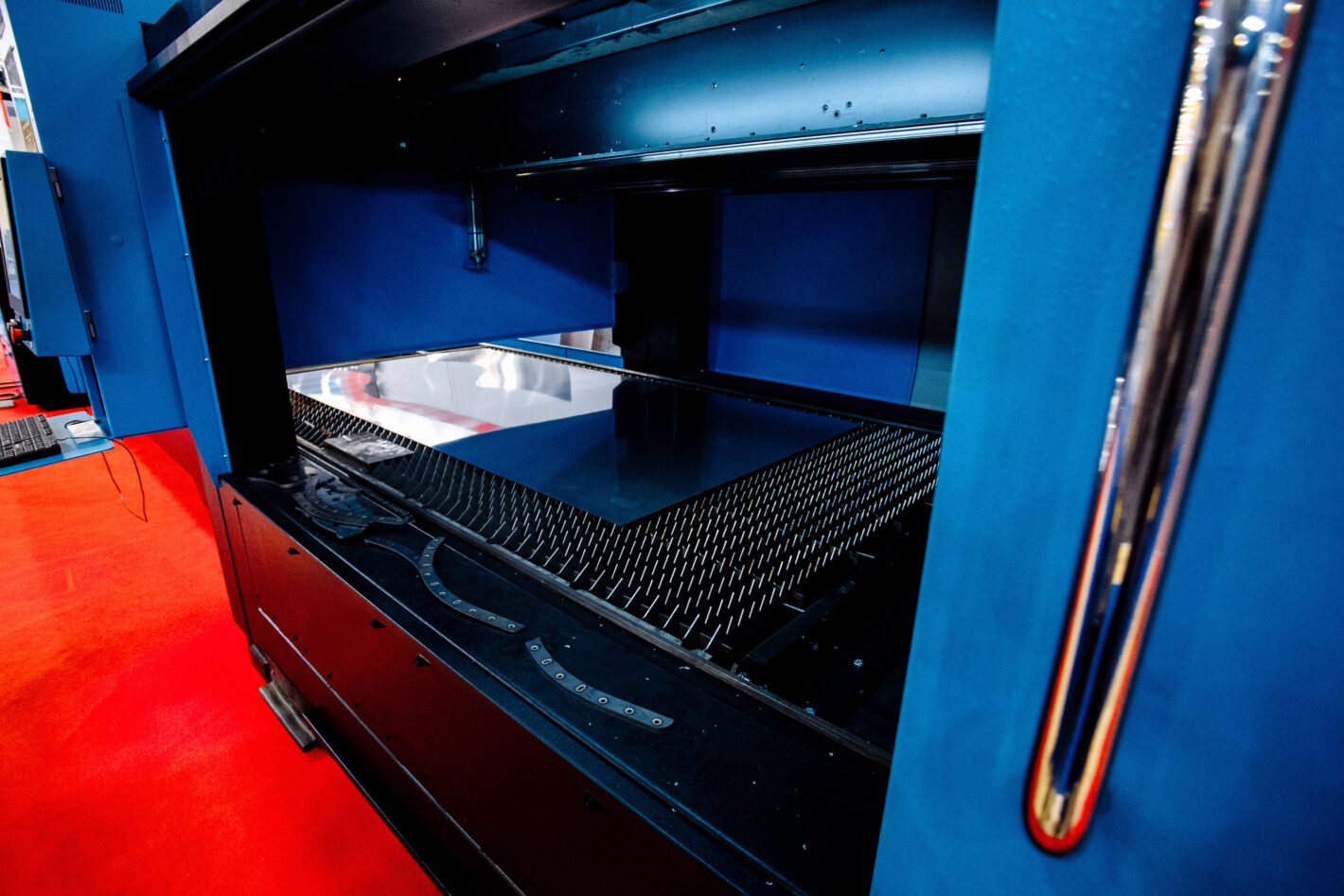

Laser cutting systems are Navicut’s own development with advanced X-axis drive technology (“Wing” system), which is a significant advantage compared to machines with a traditional gantry design of the coordinate table, which requires two synchronized motors to drive the gantry along the X-axis, high-precision parallel installation of guides and their reliable protection.

Suspended carbon Y-beam is driven by one linear motor, the magnetic road is located at the top of the O-shaped frame in the middle of the Y-beam.

This design solution provides:

- exclusion of various problems arising in the portal structure associated with the synchronization of engines and the inaccuracy of the installation of portal guides;

- high wear resistance of the moving parts of the coordinate table due to the absence of the risk of damage to the guides and motors located in the upper part of the bed beyond the reach of hot metal emissions from the cutting zone.

The “Wing” system significantly outperforms the portal structure in terms of vibration resistance and is significantly less affected by external sources of vibration (dies, presses, etc.).

Cutting complexes can be supplied with an extended coordinate table, which allows you to install a second independently operating Y-beam, a cutting head, a laser, and thereby increase the productivity of the machine by 1.8-1.9 times.