Laser cutting machine NC420

Laser cutting machine NC420 with work area 4000 x 2000 mm.

- IPG or Raycus laser sources with chiller

- Precitec or Raytools cutting head

- Linear motors or pinion rack

- Filter ventilation unit

- Powerful compressor optional

- Production and service in Serbia

- 3 years warranty

- Highlights

- Technical data

Interchangeable shuttle pallets The presence of interchangeable shuttle-type pallets without lifting the lower pallet (cutting is carried out at two levels) allows for quick replacement of workpieces, the re-rolling time is no more than 15 seconds

Z-axis acceleration is up to 3g It is important for maintaining a constant distance between the nozzle and the metal sheet at high speeds

Automatic tracking system Allows you to maintain optimal focus with an accuracy of 100 microns, which increases and stabilizes the cutting speed and results in getting a high-quality smooth surface of the cut edge

Linear motors in three axes It improves the accuracy and speed of cutting parts. We guarantee the performance of our machines and confirm this in practice

Cutting head with auto focus Precitec Procutter cutting head guarantee of reliability and quality

Due to technical know-how, we use 1 linear motor in X-axis It avoids delays when synchronizing with the second motor

Composite Y-beam, which is not subject to deformation due to temperature fluctuations Significantly improves the accuracy of machine tools compared to steel and aluminum beams

The X-axis in Navicut machines is located on top, unlike other machines Allows you to avoid sparks on cable routes during cutting

The acceleration set parameter is 28ms, one of the best values among all manufacturers Gives an advantage in the cutting speed of complex parts when many braking-acceleration cycles are required

Large weight of machines, damping system Vibration reduction and work accuracy increase

4 opening doors on both sides of the machine Facilitates the work of the operator in case of need for access to the working field. Possibility of location of the machine anywhere in the production area

CNC from B&R, one of the world leaders in industrial automation These are real-time CNCs that track the position parameters of moving parts up to the 5th derivative. Affects the speed and accuracy of data processing

The Navicut machine control software is supplied by the world leader in this field, Metalix Increases the convenience of the operator, and also allows you to use all the features of the machine

Cabinet system for all Navicut machines with door position control sensor and viewing windows Ensures safe operation

Components of world leaders French linear motors, German compressors, Italian filtration plant. Precitec laser head, IPG laser source, Japanese THK or German INA guides, IGUS flexible cable channels

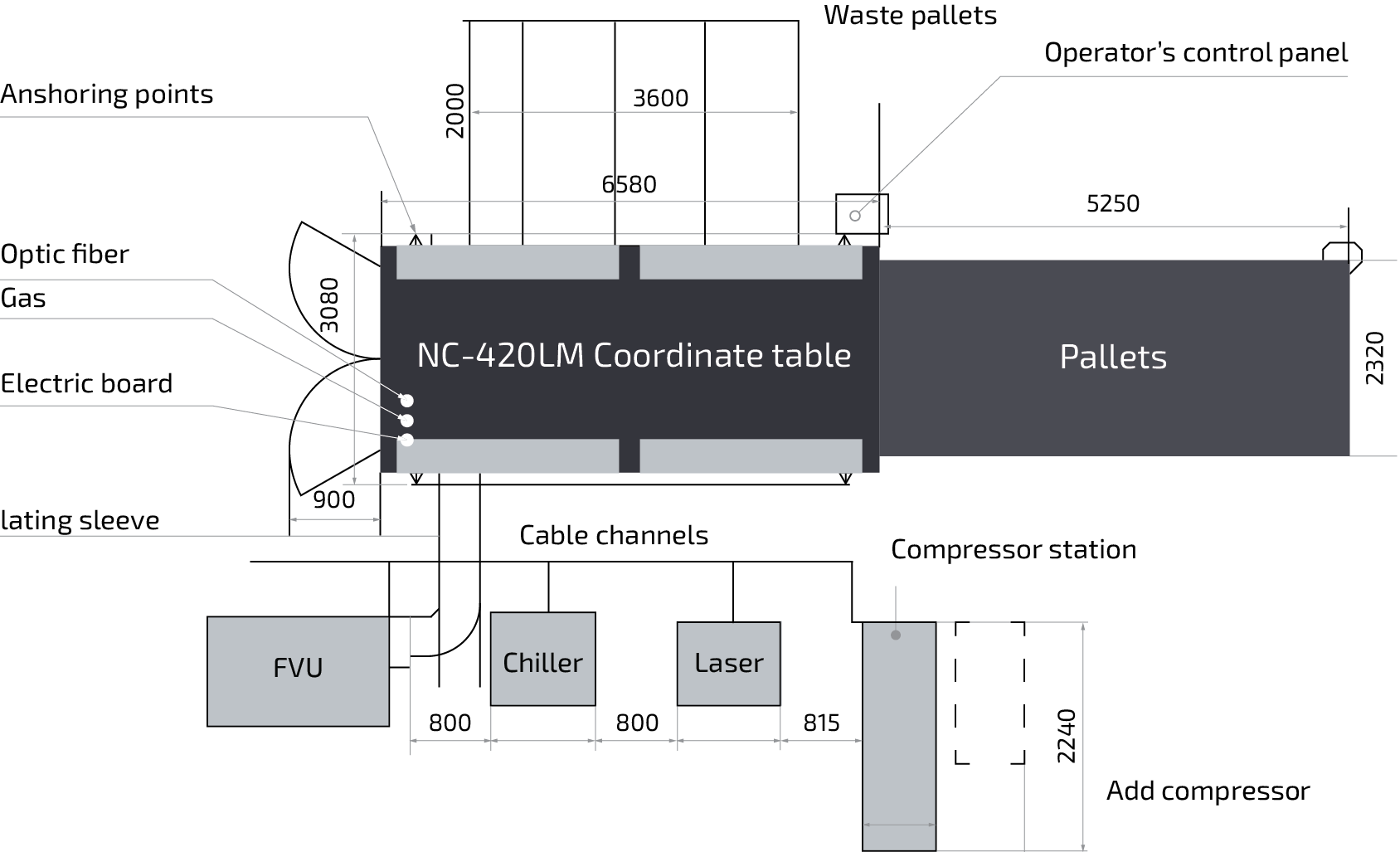

Coordinate table NC420

Processing area X/Y

4000/2000 mm

Z-axis stroke

200 mm

X and Y axis positioning accuracy

± 0.1 mm/m

Re-positioning error*

0.01 mm/m

Maximum idle speed in the X/Y plane

210 m/min

Maximum accelerations along the X/Y/Z axes

20/25/25 m/s2

Maximum load on the pallet

1300 kg

Overall dimensions of the unit in basic configuration

11830x3080x2100 mm

Coordinate table power supply

380VAC(±5%) /3F-50 Hz

Table weight

18 tons

Control system (CNC)

The in-house manufactured CNC in the Navicut machines enables working with programs from other laser equipment manufacturers. Advantages of in-house production:

all processes are controlled, including digital damping of resonant frequencies of the structure;

remote service is provided;

availability of continuous stock of components in the warehouse.

Control system type

Navicut, 17” touch screen, user interface adapted for MS Windows

CNC software

Metalix

Technological program format

G-code ISO 6983-1

Movement drive control

Direct PWM control (Direct PWM)* or servo amplifier

Interfaces for connecting additional equipment

USB, RS-232, RS-485, EtherNet, Ether Cat, StepDrive

Interpolations in the plane

Linear, circular

Linear positioning error compensation

Positioning at a point, non-pendicularity

Number of offsets

6 pcs.

Number of electrical automation control programs

200 pcs.

RAM

4 GB

Total storage capacity

500 GB

Graphical representation of the tool motion in real time

Implemented

Graphical display of the processing program

Implemented

Control of movement to restricted areas

Preliminary

Collision prevention

During processing

Tool compensation

Implemented

Automatic equipment operation log

Time of execution of a specific program, duration of operation according to the program for the period, list of control programs performed for the period, time of the machine's off state, time of the machine's on state

Control program format

ISO G-code, Fast programming patterns

Ytterbium fiber laser

Ytterbium fiber laser IPG

1,2,3,4,6,8,12,15,20,30 kW

Radiation wavelength

1070 nm

On/off time (at rated output power)

30 microseconds

Output fiber cable diameter

12 mm

Output beam quality (at the connector output)

Up to 4 mm mrad

Supply voltage

380 +-20 V/ 3F-50Hz

Production parameters

Processed metals

carbon steels, structural steels, stainless steel, electrical steels, galvanized steel, aluminum and alloys copper, titan

Gases used for cutting

Oxygen, air, nitrogen argon (for cutting titanium)

Standard arrangement of the equipment

Laser specifications Maximum thicknesses of processed metals

Maximum performance straight cutting

1 kW

2 kW

3 kW

4 kW

6 kW

15 kW

Carbon Steels

12 mm

18 mm

22 mm

24 mm

36 mm

45 mm

Alloy Steels

4 mm

10 mm

12 mm

14 mm

25 mm

40 mm

Aluminum alloys

4 mm

6.5 mm

10 mm

12 mm

14 mm

36 mm

Copper- containing alloys

3 mm

7 mm

8 mm

8 mm

12 mm

24 mm

Copper

-

4 mm

6 mm

8 mm

10 mm

14 mm

Our contacts

Learn more about our product, chat with our managers or email us.

We will reply to you as soon as possible

Entity: Navigator machines doo Beograd-Vračar

Address: Kneza stracimira 34

Place: 11118 Beograd

Registration number: 21822094

Tax: 113198154

Navicut

Manufacture: Pita Maravića br.9g, Zrenjaninski put, Beograd 11210

Office: Pita Maravića br.9g, Zrenjaninski put, Beograd 11210

Privat policy

Copyright Navicut, 2001-2024. All Rights Reserved.

Next page Catalog machine