Precision mechanical engineering

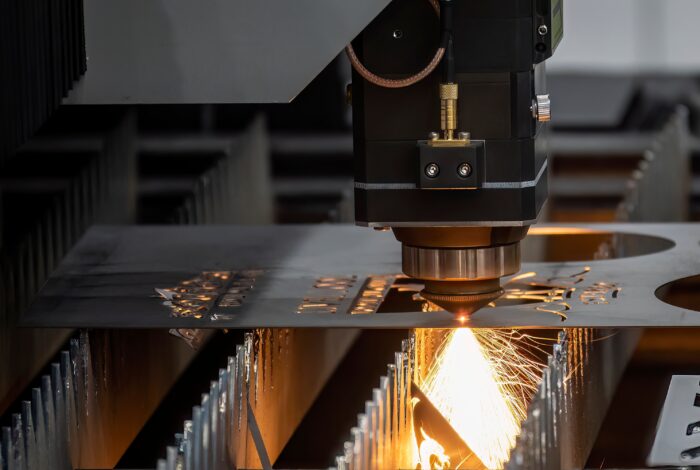

In the field of high-precision mechanical engineering, metal laser cutting machines are used with powerful sources, reliable engines and design features that allow maintaining maximum dimensional accuracy in finished products at high speed. The production of parts for the aircraft and automotive industries, components for the energy sector, machine tool building, railway transport and many other areas use laser metal cutting machines. In the manufacture of complex technical products, there is no room for error and it is important to be able to make a large number of parts in a series with the same tolerances and characteristics. Long-term performance stability of laser cutting machines is a key factor in equipment selection

Navicut Solutions

Navicut metal laser cutting machines have all of the above characteristics, which allows them to be used at the most critical stages of work. Navicut machines are able to work for a long time in 24/7 mode while maintaining the specified quality characteristics, taking a break only for scheduled maintenance. We use components only from the most famous and reliable suppliers, which guarantees the correct operation of the equipment.

The EU Declaration of Conformity allows the purchase of Navicut equipment with the participation of financing from the financial institutions of the European Union.