Software

The Metallix-Navicut technological preparation software package, supplied in cooperation with one of the world’s leading companies, automatically optimizes the cutting of parts, minimizing the time spent on preparatory operations.

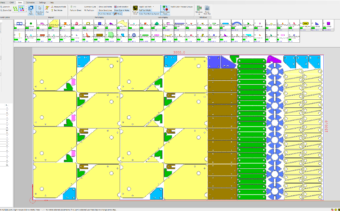

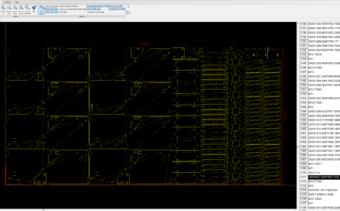

Metalix turns CAM files into NC code for your cutting machine. In a few clicks you are able to generate efficient programs while optimizing material utilization and machine runtime.

The cutting solution can be influenced by factors such as head, gas, lens, corner treatment, cutting optimization, and MicroJoints. You can modify the proposed parameters and edit the cutting tables as required.

You can easily control common line cutting, cutting part-by-part, cutting order, and any other specific way of processing the sheet.

Metalix always optimizes the chosen methods to minimize the production time, taking machine capabilities and limitations into account. The post-processor then converts these actions into efficient NC programs.

Based on predefined rules, Automatic Cutting solutions are influenced by factors such as lead-in, corner treatment, part handling, cutting optimization, MicroJoints, material, and thickness.

AutoCut processes parts efficiently and consistently, saving time and giving standard solutions for production. You can control all the parameters in one place:

- Select automatic cutting of holes and/or parts

- Determine cut entry and exit preferences

- Automatically allocate MicroJoints

- Designate corner treatment

- Optimize cuts

- Avoid collisions

- Preset part handling

- Set special processing

- Use common cuts for nested sheets

AutoCut parameters are defined per machine.

This means that a workstation with several machines can have different settings for each one.

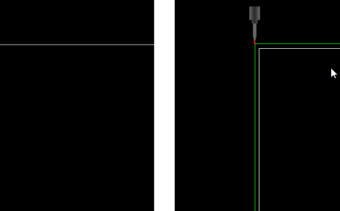

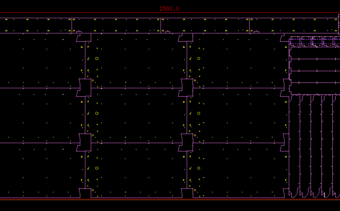

Metalix provides two types of beam compensation solutions for laser machines:

- By machine controller – The machine controller provides the compensation code.

- By Metalix – The program performs the compensation during post-processing

The first picture shows no cut offset when using controller compensation, whereas the second picture shows the offset when using Metalix compensation.

The Cutting Technology Tables allow you to define, view, and edit cutting technology parameters. The tables contain charts that cover all aspects of a material’s cutting:

- Cutting feed rate

- Cutting speed for different sized entities

- Lead-in and exit definitions for different sized entities

- Corner angles

- Overlap for holes/parts

- Detailed piercing parameters

- Detailed gas parameters

- Minimum and maximum diameters

Common cut feature allows you to process the edges of two adjoining parts with the same cut, thereby saving material, cutting gas, and time. Instead of cutting each part individually, Metalix checks if adjacent part contours are at a distance that enables using common line cutting. This powerful feature saves material, cutting gas, time, and also avoids the need to pierce the sheet again.

Benefits of common line cutting:

- Decrease machining time

- Minimize material wastage

- Save cutting gas

- Reduce wear on machine parts

Common cuts apply to these parts:

- With long, straight contours

- Cut from thick sheets, with low cutting speed

- With contours to be vaporized, requiring two passes

Our contacts

Learn more about our product, chat with our managers or email us.

We will reply to you as soon as possible

Entity: Navigator machines doo Beograd-Vračar

Address: Kneza stracimira 34

Place: 11118 Beograd

Registration number: 21822094

Tax: 113198154

Navicut

Manufacture: Pita Maravića br.9g, Zrenjaninski put, Beograd 11210

Office: Pita Maravića br.9g, Zrenjaninski put, Beograd 11210

Privat policy

Copyright Navicut, 2001-2024. All Rights Reserved.

Next page Catalog machine